If you work offshore, you know how important significant wave height (Hs) and other sea state parameters can be during operations. Before giving a green light for any activity, you need to have some insight into the local environmental conditions, ideally with as high a degree of accuracy as possible. Hs is a major factor that determines whether to execute, or otherwise to wait on weather, and investing in high quality wave sensors can aid in the optimisation of weather windows as and when they arise.

There are, however, a number of additional offshore operational challenges, beyond the limits of Hs. We outline some of these issues below, along with the ways in which Miros’ dry, digital wave and current sensor technology can help to solve them.

1. Access to Data

A common problem for companies operating offshore is access to sea state data. Such data is imperative for the safety, planning, and execution of any operation offshore but, despite having all the necessary equipment to measure waves and currents, actually accessing the resulting data is not always easy. This has to do with the way the data is gathered and stored, the format in which it is stored, and the fact that in many cases it cannot be easily shared. To put this challenge into context, before Miros’ sensor data was available in digital format, it was not uncommon for customers to ask for our help with making their own data accessible to relevant stakeholders, either within or outside their organisation.

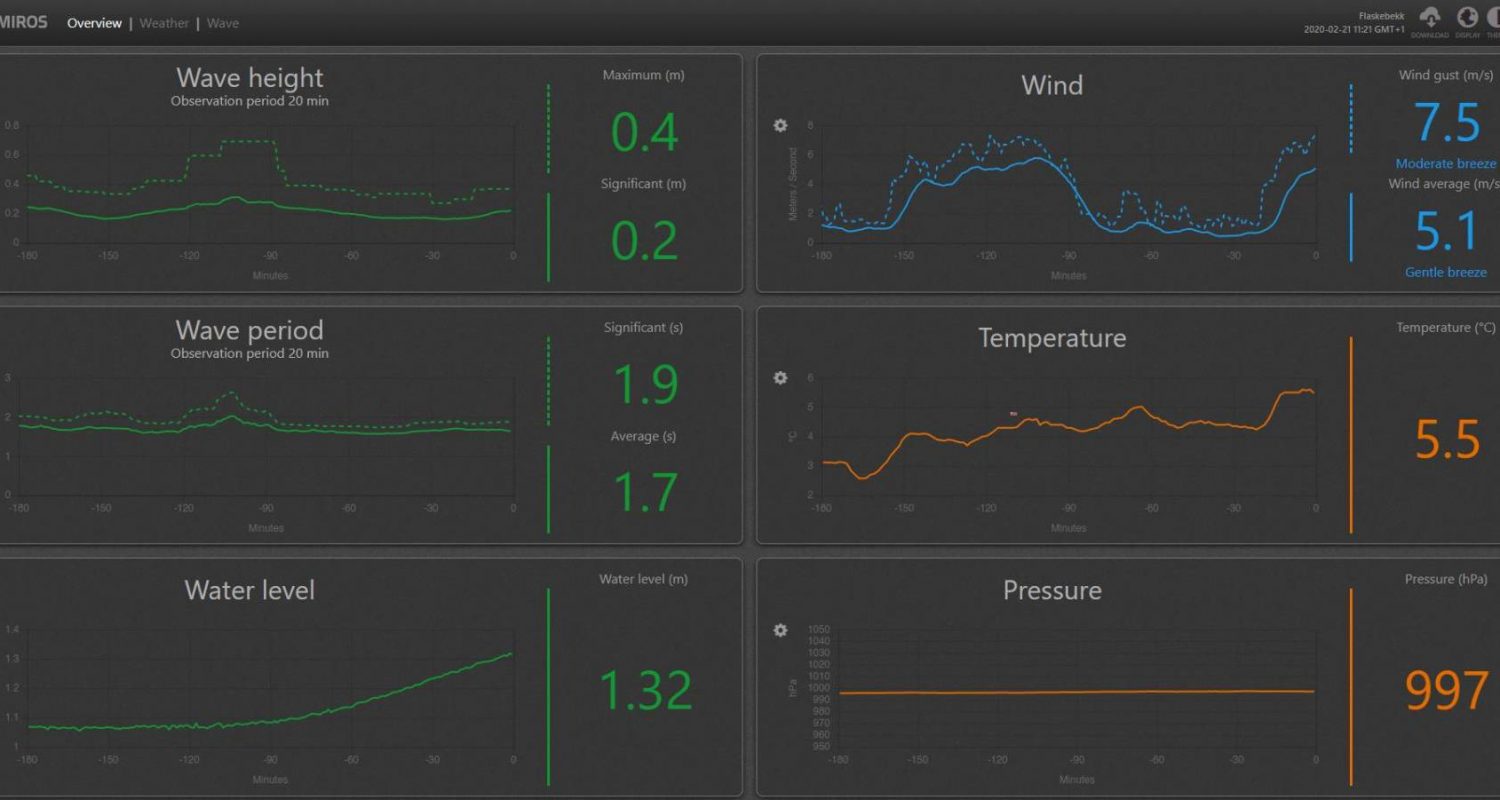

Miros’ portfolio of IoT-enabled digital sensors solves this problem. Customers can easily view, manage and access their data through a secure web-based graphical user interface and then share their data with anyone within, or outside, their organisation. Plus, when they need to access historical data they can download it with a single button click.

2. Sensor Maintenance

Most sea state sensors are submerged in water. This means significant wear and tear, as well as complications associated with biofouling, all of which require frequent maintenance with high associated costs and risks. In contrast, all of Miros’ sensors are dry-mounted and measure remotely. Consequently, none of Miros’ equipment is subject to the forces of the ocean, making the sensors practically maintenance free. They measure accurately, irrespective of weather conditions, gathering data undisturbed by waves, currents, fog, rain or water spray. We’ve even seen them gather data through hurricanes and typhoons, without issue.

3. Deployment and Retrieval

Installation of in-water instruments is a complex exercise. Their deployment requires time, planning and expensive resources such as vessels and divers. Additionally, the same exercise needs to be repeated whenever the equipment is retrieved for maintenance, repair or decommissioning. Miros sensors, on the other hand, are “plug & play”, meaning customers can either install them with our remote support, or our field engineers can support them on site. There is no need for costly, time-consuming deployment and retrieval of equipment. To start gathering and sharing sensor data is just a matter of connecting to power and the Internet.

4. Loss of Equipment

In-water equipment, such as buoys, often gets lost at sea during winter storms and typhoons. Another common problem is that the equipment gets stolen by pirates or damaged by dubious fishing practices. This is very costly and leads to loss of data over extended periods of time. Miros sensors are installed on the asset, whether that is a vessel, an oil rig, an offshore wind turbine, or a substation. The risk of losing the equipment is minimal, as is the risk of downtime.

5. Complex Installation Process

In the past, metocean and sea state equipment has typically been time-consuming and complex to install and integrate. Miros equipment, in comparison, is extremely easy to install which, in some instances, allows the customer to do so themselves, eliminating the need for the deployment of external personnel on the offshore asset.

6. Time-Consuming and Costly Sensor Calibration

Calibration of wave spectra and integrated wave parameters from radar-based measurement systems has historically depended upon external reference sensors, such as wave buoys. This process is associated with high costs, significant delays, and an assortment of practical challenges. Miros’ sensors support fully automatic calibration, providing the user with high-quality wave and current parameters for a broad range of radar types and measurement conditions, without the need for manual calibration. The elimination of calibration procedures dramatically reduces installation and operational costs.

7. Noisy Data

When measuring surface currents and speed through water (STW) from aboard vessels, the process of gathering good quality data has not always been straightforward. When using in-water equipment, vessel and propeller motion, as well as water turbulence and air bubbles, cause disturbances that result in “noisy” data. Miros’ solution measures surface currents and STW remotely, making measurements ahead of the vessel, providing accurate, reliable data undisturbed by vessel motion and other sources of significant noise.

8. Slow Upgrades and Low-Quality Data

Making sure the sensor software on an asset or vessel is up to date is not always a top priority during offshore operations. Therefore, sensor software can quickly become outdated, potentially leading to sub-optimal data quality. The Miros portfolio of sensors are Cloud integrated, allowing for secure local and remote access. This lets Miros’ support team remotely upgrade all sensor software, as agreed with the customer, ensuring that sensors are always equipped with the latest version of the software. Additionally, this allows the support team to closely follow your sea state data, ensuring that it is always of optimal quality.

9. Risky Investments

Purchasing and owning sensor equipment to use on an offshore asset or a vessel can be a risky and time-consuming business. Miros’ portfolio of sensors is offered as-a-Service. This takes the risk of owning equipment out of our customers’ hands and introduces a lower upfront investment option, more flexibility, and greater convenience. The aaS subscription plan includes relevant sensor hardware and software, as well as the full suite of Miros Cloud services. It also includes sensor maintenance, spare parts and insurance. Furthermore, Miros takes on all of the responsibility of maintaining the infrastructure required to deliver your secure, reliable data. This data can be securely accessed anytime, anywhere and on any device.

10. Lack of Scalability

As previously discussed, access to, as well as sharing of, data from sensors supporting offshore operations can be a tricky business. This impedes the efficiency and scalability of offshore operators.

The fact that Miros sensors can now be connected to a secure Cloud-based platform allows for real-time data sharing between all stakeholders in an operation, enabling those stakeholders to share a common overview of local conditions as they develop. Thus, the ability to share digital sea state data in real time between an unlimited number of stakeholders, both on- and offshore, improves situational awareness, supports decision-making and contributes to significant efficiency enhancements. Easy sharing of digital data also means easy access to historical data, for improved planning, tendering and incident analysis, all of which supports scalability.

Access to accurate sea state data is essential for all offshore operators. Miros sensors deliver high quality sea state data, and thanks to the fact that the sensors are IoT based, Cloud integrated, and can be delivered as-a-Service, they can also help solve some of the most common offshore operational challenges related to metocean and sea state monitoring equipment in general.