Background

One of Europe’s largest gas processing plants on the West coast of Norway receives gas from around 30 fields in the North Sea and processes 25 per cent of all natural gas from Norway. The plant was built to receive and process gas in 1985, meaning the pipeline needs to be inspected and maintained regularly. This makes the requirement to accurately monitor the surrounding seas state crucial.

The Challenge

The pipeline coming into the processing plant consists of a large underwater-inshore concrete construction which needs regular risk-based inspection. This inspection and the resulting maintenance was carried out by divers, making it necessary to have accurate information about the sea state to safeguard the diver. Sending divers out without being aware of wave height and direction can be very risky and, in some cases, even life-threatening. It was important to gather data about the ocean surface throughout the course of the year to better understand the intensity of the ocean forces the pipeline was exposed to. Until recently, the operator relied on buoys and weather forecasts for gathering the information but found that the required maintenance and the related costs were an inefficient solution in the digital age.

The Solution

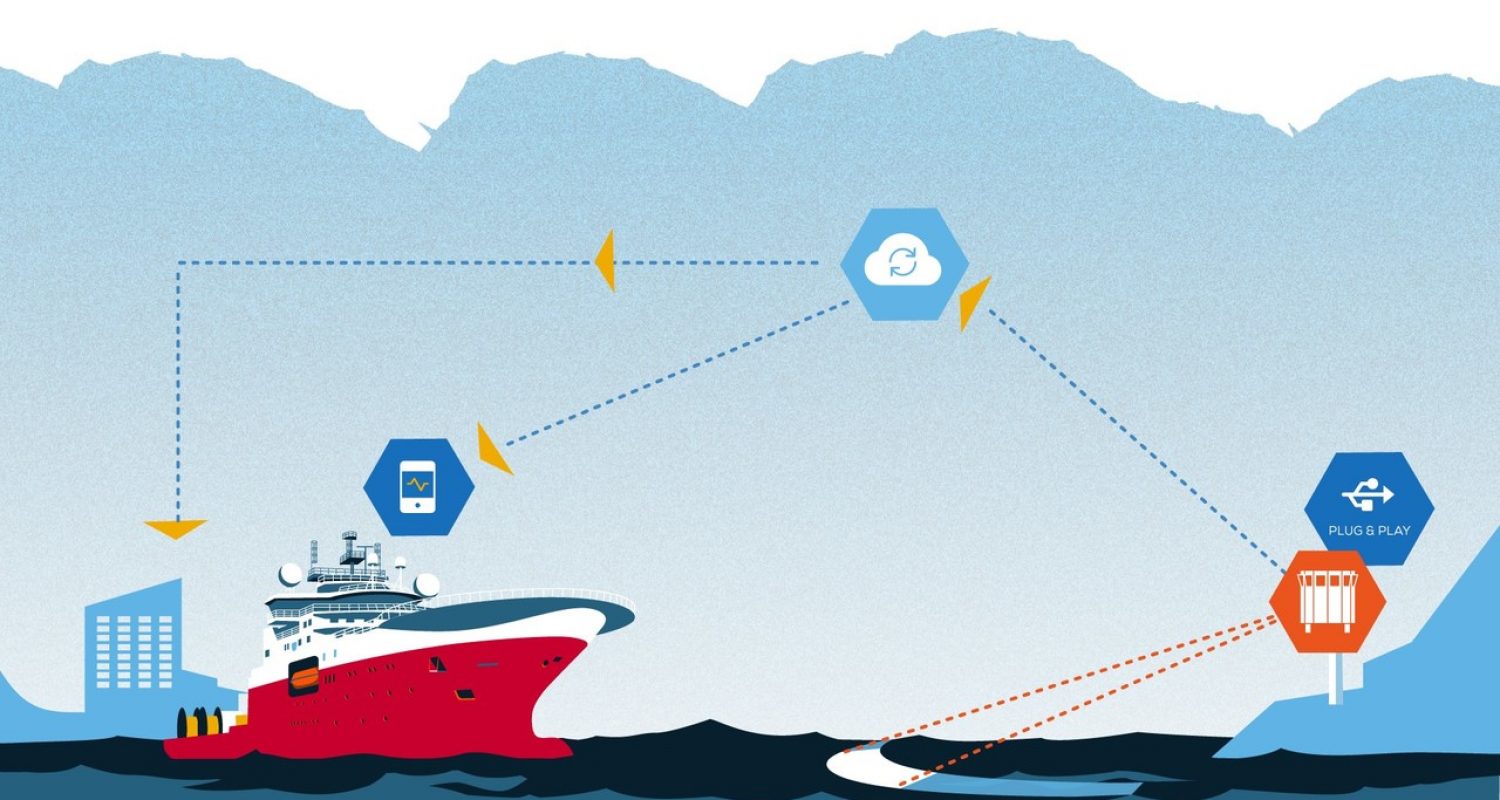

The operations and maintenance teams decided to try out Miros’ new cloud-integrated Wave and Current Radar (SM-050) to ensure the safety of their divers while eliminating the high maintenance costs of a wave buoy. The Miros solution is a dry, permanent radar which due to its robustness eliminates the risk and cost related to maintenance. Hence, with the dry radar the need for expensive operations related to buoy deployment and recovery is avoided. The cloud-integrated radar also brings the benefit of easy access to data anytime and anywhere.